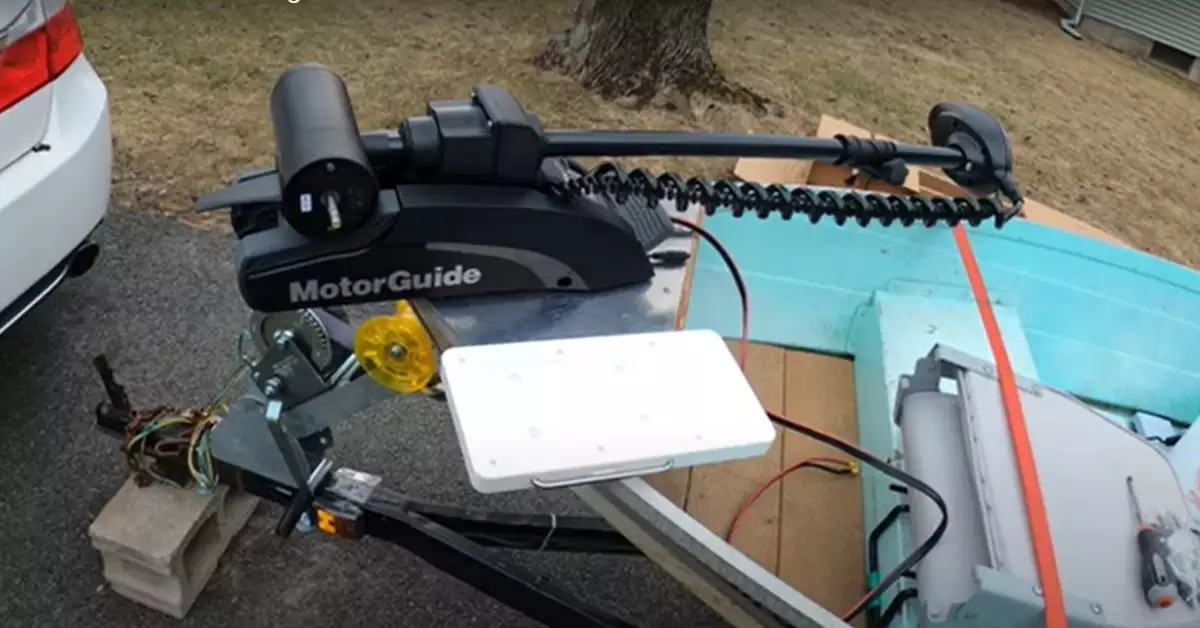

Trolling motors, an essential component for many boating enthusiasts, transform a simple boat into a fishing haven. Pair that with the lightweight and durable structure of an aluminum boat, and you have a match made in heaven.

A trolling motor’s purpose is to propel a boat at a steady pace, allowing for smoother fishing experiences. Mounting it on an aluminum boat is a straightforward process.

The durability and lightweight nature of aluminum boats make them an ideal choice for many. When equipped with a trolling motor, they offer enhanced maneuverability and fishing capabilities.

Types of Trolling Motors

Trolling motors come in various designs, each tailored for specific mounting positions on the boat:

Bow-mounted Trolling Motors

These are placed at the front of the boat and offer precise steering for the angler.

Transom-mounted Trolling Motors

Typically mounted on the rear, these are perfect for smaller boats and provide excellent push power.

Engine-mounted Trolling Motors

Installed adjacent to the primary outboard motor, these work in tandem with the main engine for increased propulsion.

Preliminary Steps

Embarking on the installation of a trolling motor requires some foundational steps. These not only assure a smoother process but also ensure that the end result is both functional and safe.

Select the Perfect Motor:

Every boat, depending on its size, weight, and purpose, requires a specific kind of trolling motor. Making an informed choice guarantees efficiency and longevity:

- Boat Size and Weight: This is paramount. A larger, heavier boat demands a trolling motor with greater thrust power. Conversely, a small, lightweight boat does not need a heavy-duty motor.

- Freshwater vs. Saltwater: Motors specifically designed for saltwater are crafted to resist corrosive elements. Using a freshwater motor in saltwater environments can drastically reduce its lifespan.

- Voltage Requirements: Trolling motors come in 12V, 24V, and 36V. A longer time on the water typically means a higher voltage motor is beneficial.

Tools At Hand:

Having the right tools from the onset can significantly streamline the process:

- Screwdriver Set: Different screws may be used in the mounting process, making a diverse set handy.

- Drill with Various Bits: A drill is essential for creating attachment points. Various bits cater to different screw sizes and types.

- Clamps and Mounting Hardware: These secure the motor in place. It’s crucial they’re robust and rust-resistant, especially for saltwater usage.

- Wire Strippers and Connectors: If your motor doesn’t come with a pre-installed plug, these tools will be crucial for connecting to the power source.

Bow-mounted Trolling Motors: Installation Steps

Mounting a trolling motor at the boat’s bow allows for better boat control and precise movements, especially during fishing:

Spot Selection:

Picking the right location can influence the motor’s effectiveness:

- Obstruction-Free Area: This ensures that the propeller has free movement, reducing chances of entanglement or damage.

- Easy Accessibility: The chosen spot should be easily accessible for operations and maintenance, while not hindering boat entry and exit.

Drilling and Bracket Securement:

The key is precision:

- Mark Drilling Points: Before drilling, measure and mark the spots to avoid mistakes. Using a template can be helpful.

- Drill with Care: Ensure the boat’s other side is clear. Use a piece of wood underneath the drilling point to avoid any punctures.

- Secure the Motor Bracket: Using rust-resistant screws, attach the bracket firmly. Any wobble can reduce the motor’s efficiency.

Connection Phase:

A seamless power connection ensures optimum motor function:

- Link to Power Source: Use high-quality connectors, ensuring they are properly insulated to prevent short circuits.

- Steering Mechanism Test: Before venturing out, test the motor’s steering to ensure it’s responsive and accurate.

Transom-mounted Trolling Motors: Installation Process

Rear mounting offers an advantage for smaller boats or those who prefer rear propulsion:

Pinpointing Mounting Location:

The location can affect balance:

- Transom’s Integrity Check: Before mounting, check the transom’s condition. A weak or damaged transom can’t effectively support a motor.

- Centralized Spot: Aim for a central spot to ensure balanced propulsion, but remember, slightly off-center is often ideal for steering accuracy.

Clamping and Ensuring Stability:

Stability is crucial:

- Strong Clamps: Ensure the clamps are not only strong but also corrosion-resistant, especially if used in saltwater.

- Stability Test: Once clamped, give the motor a gentle shake to ensure it’s firmly attached.

Power Pathway Setup:

An organized power setup prevents mishaps:

- Clean Route for Power Cables: Organize the cables, using zip ties if necessary, ensuring they aren’t in areas of frequent movement.

- Battery Connection: When connecting, always ensure you’re following the correct polarity. Misconnections can damage the motor.

Engine-mounted Trolling Motors: How to Set Up

Engine-mounted trolling motors complement the main engine, providing additional power when needed:

Pondering Position:

Choosing a position is about balance and function:

- Motor Side Selection: Whether port or starboard, the side chosen should not obstruct the primary engine or any other crucial components.

- Non-Interference with Main Engine: Ensure the trolling motor doesn’t interfere with the main engine’s operation or exhaust.

Main Engine Link:

Connecting it to work alongside the main engine:

- Parallel Operation: The trolling motor should function parallelly, supplementing the main engine especially during slow-speed maneuvers.

- Optimal Propeller Depth: Ensure the trolling motor’s propeller is deep enough to avoid cavitation but not so deep as to be inefficient.

Control Systems Introduction:

Control is everything:

- Steering and Speed Control: Modern trolling motors come with foot or hand controls. Familiarize yourself with these for smooth operation.

- Test for Smoothness: Ensure all controls work harmoniously, without any jerks or unexpected movements.

Safety Measures While Installing

Mounting a trolling motor requires caution:

- Power Precautions:

- Always disconnect batteries before installation.

- Safety Gear Essentials:

- Wear gloves and safety goggles.

- Post-install Water Testing:

- Ensure the motor operates correctly.

- Check for any abnormalities or leaks.

Maintenance Tips

To prolong the life of your setup:

- Routine Inspections:

- Check for loose parts or wear.

- Cleanliness Counts:

- Wipe down the motor after each use.

- Avoid letting debris build up.

- Store Smart:

- When not in use, store in a dry, cool place.

- Cover to prevent dust accumulation.

Frequently Asked Questions

Can I switch the type of trolling motor after installation?

Yes, but it might require adjusting the mounting setup or purchasing additional components.

How often should I inspect my trolling motor?

For regular users, a monthly check is advisable. For occasional users, inspecting before and after each use is sufficient.

Are there weight limits to consider when choosing a trolling motor?

Absolutely. Always match the trolling motor’s thrust capacity with your boat’s weight to ensure effective propulsion.

Conclusion

The inclusion of a trolling motor on an aluminum boat elevates the overall boating experience, offering precision, speed, and an edge in fishing endeavors.

For a seamless operation, regular maintenance, and periodic checks, ensure the trolling motor’s longevity and efficient operation.

A well-installed trolling motor is not just about the installation process but also about ongoing care, ensuring that each trip on the water remains a pleasurable adventure.